ENOVENETA S.P.A.

Nel corso di oltre 50 anni di intensa ricerca, sviluppo e produzione di soluzioni tecnologiche per la vinificazione, l’azienda è diventata un punto di riferimento internazionale. Oggi Enoveneta è in grado di gestire ogni progetto dal dimensionamento alla messa in funzione dell’impianto, fornendo tutte le tecnologie necessarie.

1962

Anno di fondazione

60+

Dipendenti

40000 m2

Superficie produttiva

100+

Paesi serviti

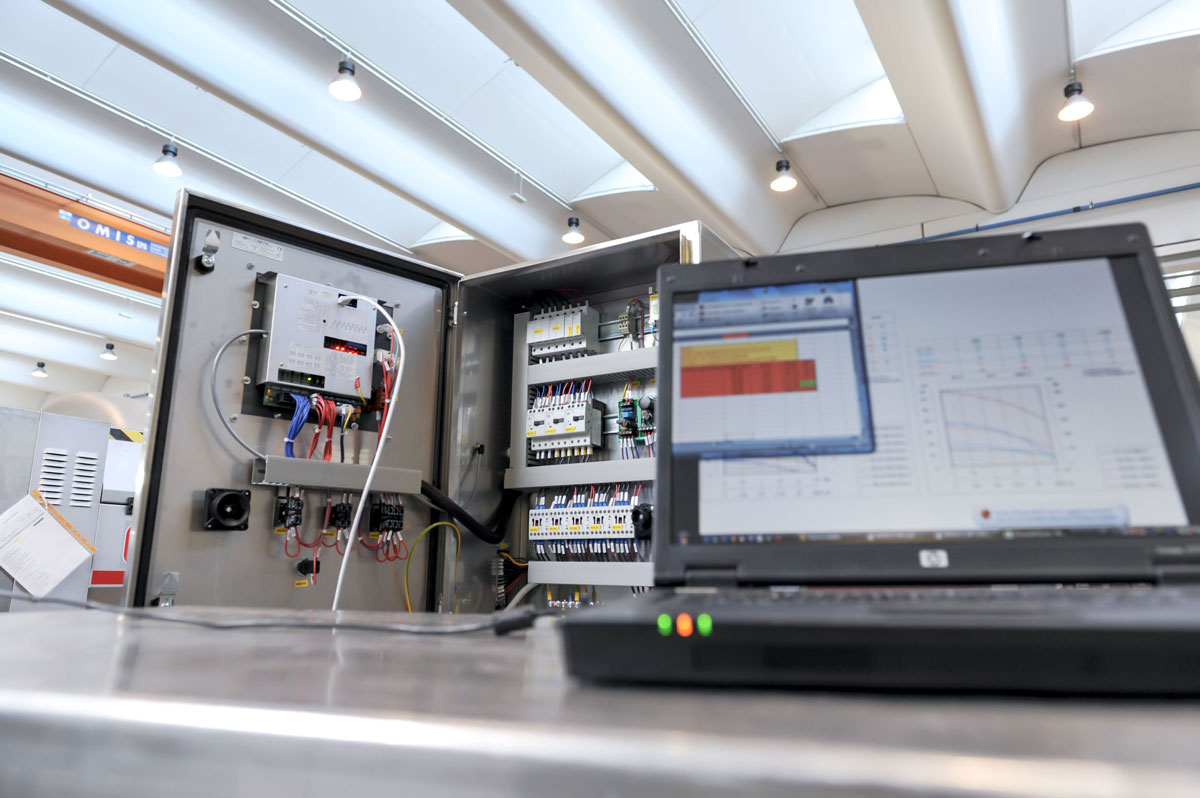

Industria 4.0

Enoveneta realizza soluzioni tecnologiche che, grazie all’utilizzo di sensori e all’interconnessione tra le varie macchine, possono integrarsi in impianti produttivi 4.0. È possibile ottimizzare la produzione e interconnettersi con i sistemi informativi aziendali.

Cerchi assistenza?

Enoveneta offre un servizio post-vendita a livello mondiale, sia attraverso centri autorizzati che tramite interventi diretti. Il nostro team, composto da tecnici con esperienza pluriennale nel settore, garantisce un servizio attento e capillare.

Le nostre tecnologie in evidenza

Diraspatrici TOP

Modelli con lavorazioni orarie dalle 5 alle 120 ton/h, interamente costruite in acciaio inox AISI 304.

Presse pneumatiche ad azoto ATMOS

Modelli con capacità da 9 a 330 hl,

interamente costruite in acciaio inox AISI 304.

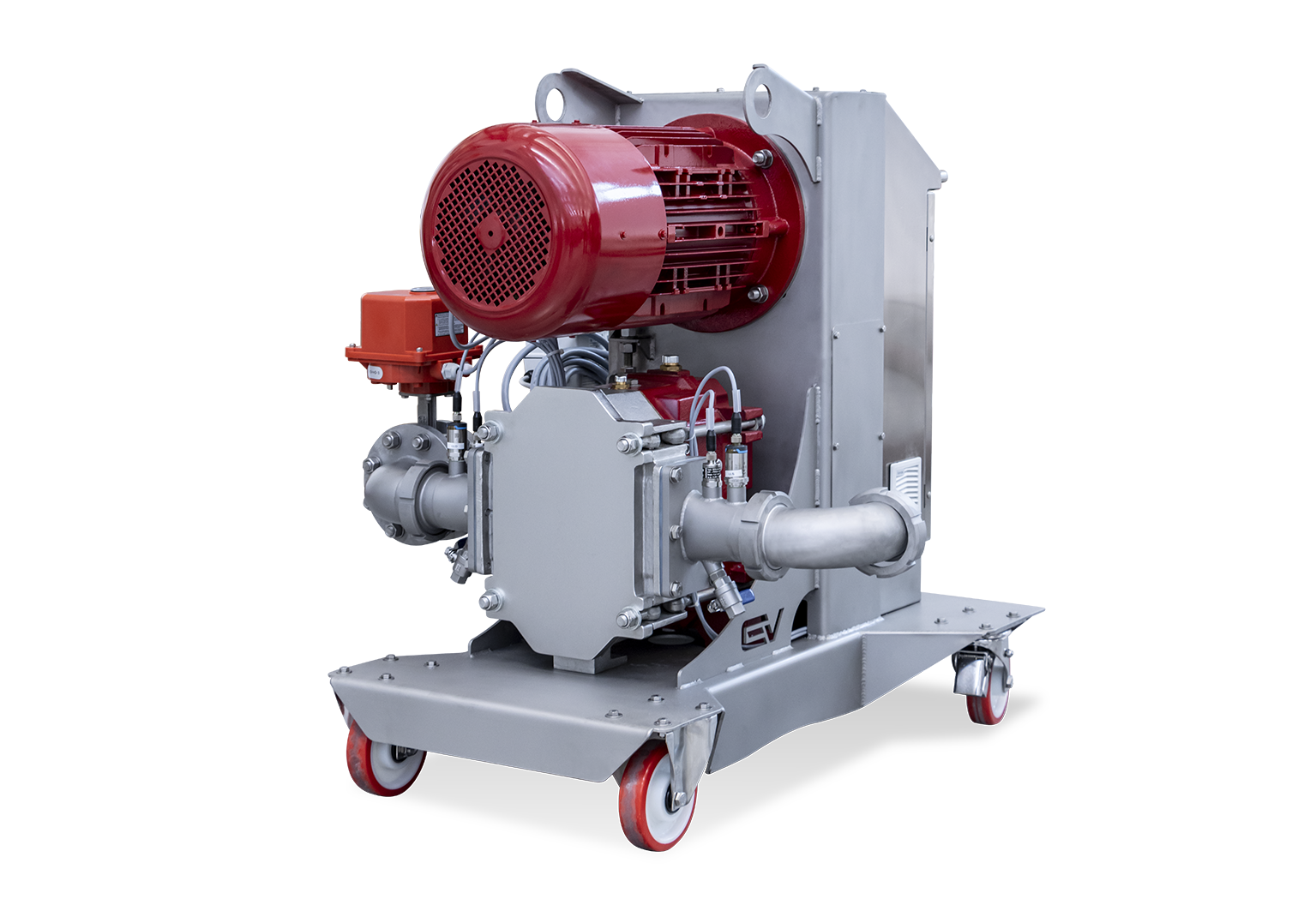

Pompe a lobi LOBEV

Modelli con portate da 25 a 700 hl/h,

disponibili con lobi standard o elicoidali.

I nostri punti di forza

MIGLIORAMENTO CONTINUO

Ci impegniamo, anno dopo anno, a raggiungere nuovi traguardi in termini di eccellenza qualitativa e di personalizzazione dell'offerta. Questo grazie ad una costante ricerca e sviluppo anche in settori analoghi a quello della vinificazione.

SERVIZIO A 360°

Grazie ad un'esperienza pluriennale nel campo della vinificazione, siamo in grado di garantire la massima personalizzazione e flessibilità produttiva a seconda delle esigente del cliente. Questo ci permette di fornire soluzioni complete "chiavi in mano".

ASSISTENZA CAPILLARE

Filiali aziendali estere ed una rete internazionale capillare di agenti e distributori. Questo ci permette di rispondere in modo rapido ed efficace ad ogni cliente, ovunque esso si trovi.