A unique technology, that can be fitted into many production phases, always preserving the product quality

Every wine producer have a main objective: transfer the wine gently without compromise all the organoleptic chracteristics. For that reason Enoveneta has designed the PL series lobular pumps with standard and helicoidal lobes. These pumps are perfect for any type of customer, from the small winery to the big wine producer.

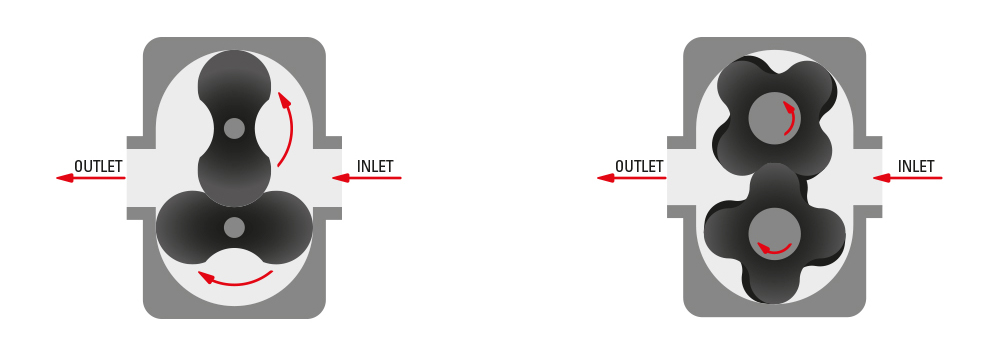

On this type of pumps two lobular rotors rotate synchronous on two parallel axes. During the rotation the lobes move the product from the inlet to the outlet making a continuous flow.

A small number of rotations and a constant working temperature characterize the PL pumps. These technical features allow to treat the product gently avoiding grapes damage, during the transfer of whole grape, or foam formation, during the liquid transfer.

The versatility of our pumps allow to use them on transferring from tank truck, pouring, refrigeration, bottling and many other vinification phases.

Technical features

All PL series pumps are built in stainless steel and all the moving parts are built with high wear resistance materials. Also, lobes are coated with a food safe rubber that allow to transfer any type of product delicately. All our models are complete of electronic speed variator, remote cable control and liquid detection probe.

There are different models available: on wheels, with fixed supports or flanged on conveyor hoppers, and with different dimensions and flow rates in order to meet every needs. Our lobular pumps have flow rates from 80 to 1000 hl/h and hydraulic head up to 40 meters. The accessories list include the electromagnetic liters counter, the remote radio control, the lighting flow indicators and the enzymes dosing pump. The wide range of accessories allow the customer to customize completely his lobular pump.